- 您现在的位置:买卖IC网 > Sheet目录19083 > DCE.91.132.BVM (LEMO)TOOL POSITNER FOR DPC.91.701.V

�� �

�

�

�?�

�?�

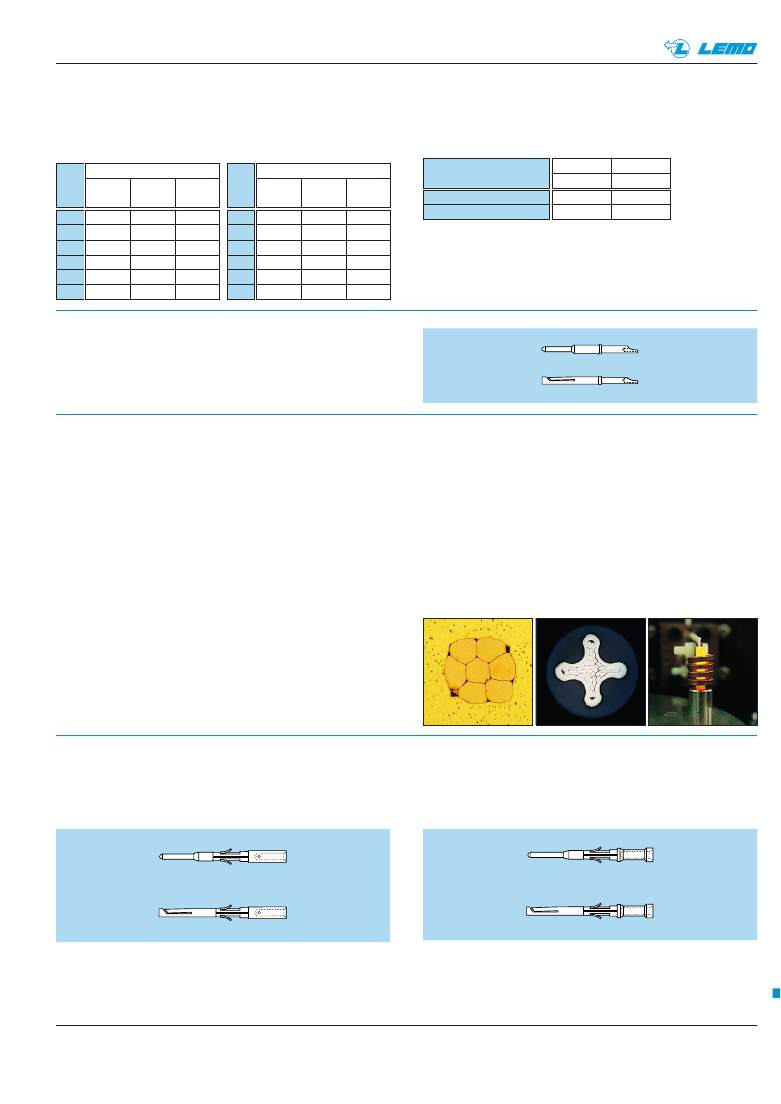

�Contact� resistance� with� relation� to� the� number�

�of� mating� cyles�

�(measured� according� to� IEC� 60512-2� test� 2a)�

�Average� values� measured� after� the� mating� cycles� and� the�

�salt� spray� test� according� to� IEC� 60512-6� test� 11f.�

�Insulation� resistance� between� the� contacts�

�and� contact/shell�

�(measured� according� to� IEC� 60512-2� test� 3a)�

�A?�

�(mm)�

�Contact� resistance� (m� ?� )�

�1000� 3000� 5000�

�cycles� cycles� cycles�

�A?�

�(mm)�

�Contact� resistance� (m� ?� )�

�1000� 3000� 5000�

�cycles� cycles� cycles�

�Insulating� material�

�new�

�Multipole�

�PEEK�

�>� 10� 12� ?�

�Unipole�

�PTFE�

�>� 10� 12� ?�

�0.5�

�7.5�

�8.3�

�8.7�

�3.0�

�2.0�

�2.2�

�3.1�

�after� humidity� test� 1)�

�>� 10� 10� ?�

�>� 10� 10� ?�

�0.7�

�0.9�

�1.3�

�1.6�

�5.6�

�4.1�

�2.8�

�2.6�

�5.7�

�4.2�

�2.9�

�2.7�

�6.1�

�4.8�

�3.6�

�3.5�

�4.0�

�5.0�

�6.0�

�8.0�

�1.6�

�1.4�

�1.2�

�0.8�

�2.0�

�–�

�–�

�–�

�2.8�

�–�

�–�

�–�

�2.0�

�2.9�

�3.1�

�3.3�

�12.0�

�0.7�

�–�

�–�

�Note:� 1)� 21� days� at� 95%� RH� according� to� IEC� 60068-2-3.�

�Solder� contacts�

�The� conductor� bucket� of� these� contacts� is� machined� at� an�

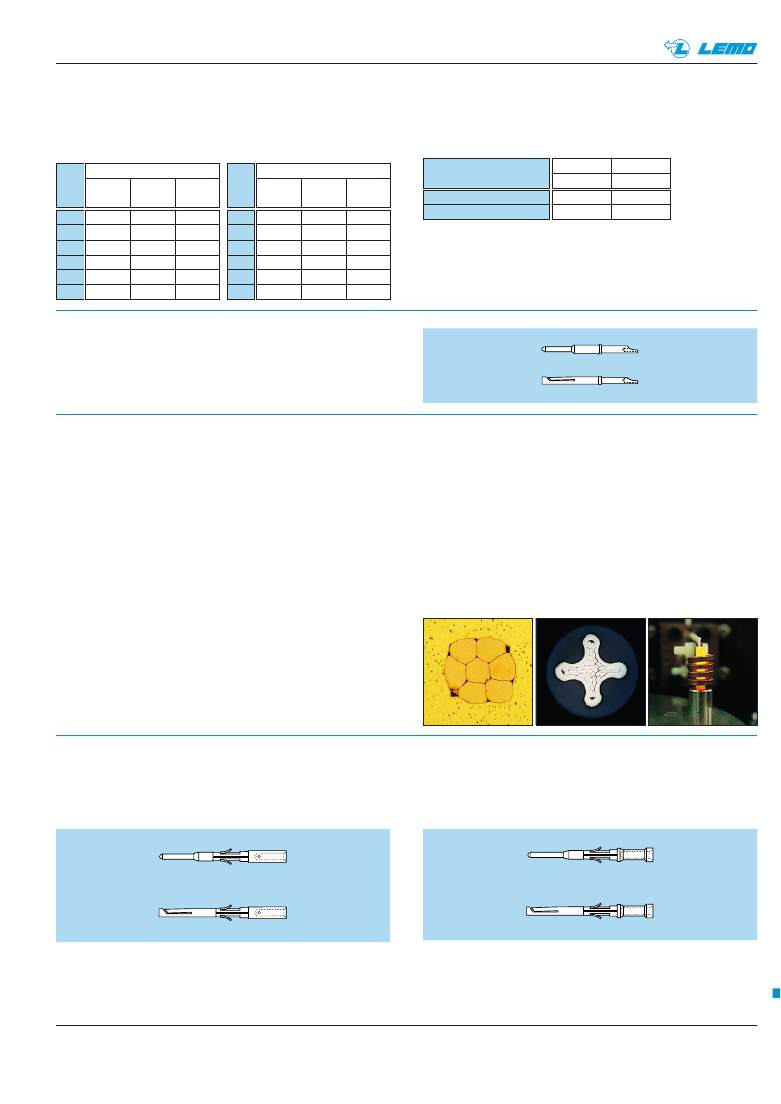

����Crimp� contacts�

�The� square� form� crimp� method� is� used� (MIL-C-22520F,�

�class� I,� type� 2)� photo� 1� for� unipole� contacts.�

�For� multipole� contacts� the� standard� four� identer� crimp�

�method� is� used,� MIL-C-22520F,� class� I,� type� 1),� photo� 2.�

�The� crimp� method� requires� a� controlled� compression� to�

�obtain� a� symmetrical� deformation� of� the� conductor� strand� and�

�of� the� contact� material.� The� radial� hole� in� the� side� of� the� con-�

�tact� makes� it� possible� to� check� whether� the� conductor� is�

�correctly� positioned� within� the� contact.� A� good� crimping� is� char-�

�acterized� by� only� slightly� reduced� conductor� section� and�

�practically� no� gap.�

�Advantages� of� crimping�

�–� practical,� quick� contact� fixing� outside� the� insulator�

�–� possible� use� at� high� temperature�

�–� no� risk� of� heating� the� insulator� during� the� conductor-�

�contact� fixing�

�–� high� tensile� strength�

�Crimp� contacts� are� available� in� standard� version� (form� 1)� for�

�mounting� maximum� size� conductors.�

�For� some� dimensions,� these� crimp� contacts� can� be� pro-�

�duced� with� reduced� crimp� barrels� (form� 2)� for� mounting�

�reduced� size� conductors.�

�For� optimum� crimping� of� bronze� or� brass� contacts� they� are�

�annealed� to� relieve� internal� stress� and� reduce� material�

�1�

�2�

�3�

�hardening� during� the� crimping� process.�

�Only� the� crimping� zone� is� annealed� with� the� help� of� an�

�induction� heating� machine� designed� by� the� LEMO� Research�

�and� Development� Department� (see� photo� 3).�

�Crimp� contacts�

�The� crimp� contacts� can� be� with� two� forms:� a� standard� crimp�

�barrel� for� large� conductors� (see� fig.� 1)� or� with� a� reduced�

�crimp� barrel� for� smaller� conductors� (see� fig.� 2).�

�Fig.� 1�

�www.lemo.com�

�The� range� of� cable� dimensions� that� can� be� crimped� into�

��Fig.� 2�

�177�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

FXO-HC335R-14.31818

OSCILLATOR 14.31818 MHZ 3.3V SMD

OV4ZBBBB

LED OPTIMAL IV STAR BLUE

8W-26.000MBA-T

OSC 26.000 MHZ 3.3V SMT

P51-50-S-F-P-5V-000-000

SENSOR 50PSIS 1/4 NPT 5V

P51-15-S-F-P-5V-000-000

SENSOR 15PSIS 1/4 NPT 5V

P51-750-S-E-P-5V-000-000

SENSOR 750PSIS 3/8 UNF 5V

P51-500-S-E-P-5V-000-000

SENSOR 500PSIS 3/8 UNF 5V

DCE.91.131.BVC

TOOL POSITNER FOR DPC.91.701.V

相关代理商/技术参数

DCE.91.132.CVC

功能描述:折皱器 PSTNR F. CRMP CONTCT

RoHS:否 制造商:Hirose Connector 类型: 描述/功能:Cable and Shield Crimper

DCE.91.132.CVM

功能描述:折皱器 PSTNR F. CRMP CONTCT

RoHS:否 制造商:Hirose Connector 类型: 描述/功能:Cable and Shield Crimper

DCE.91.133.BVC

功能描述:折皱器 POSITNER F CRIMP CTS

RoHS:否 制造商:Hirose Connector 类型: 描述/功能:Cable and Shield Crimper

DCE.91.133.BVCM

制造商:LEMO connectors 功能描述:

DCE.91.133.BVCW

功能描述:折皱器 B-SERIES M/F POSITNR SMPTE 3K 1.3mm CRMP

RoHS:否 制造商:Hirose Connector 类型: 描述/功能:Cable and Shield Crimper

DCE.91.133.BVCY

制造商:LEMO 功能描述:TOOL POSITIONER FOR CRIMP PIN 制造商:LEMO connectors 功能描述:TOOLING - DCE.91.133.BVCY

DCE.91.133.BVM

功能描述:折皱器 PSTNR F. CRMP CONTCT

RoHS:否 制造商:Hirose Connector 类型: 描述/功能:Cable and Shield Crimper

DCE.91.134.BVC

功能描述:折皱器 PSTNR F. CRMP CONTCT

RoHS:否 制造商:Hirose Connector 类型: 描述/功能:Cable and Shield Crimper